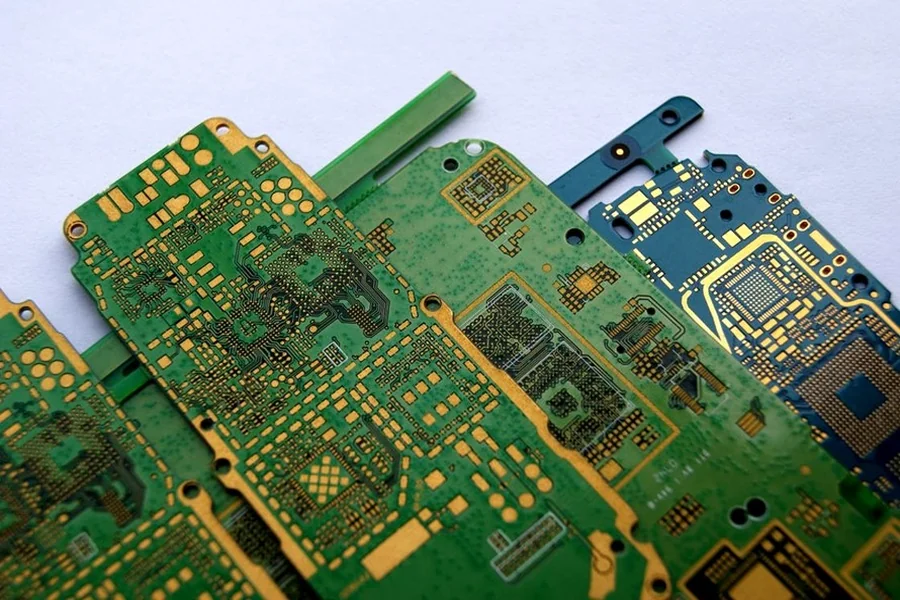

In the expansive world of electronics, circuit boards form the foundation of nearly every device. Among the different types of printed circuit boards, the Single-Sided PCB Board stands out for its simplicity and cost-efficiency. This basic yet vital board plays a significant role in powering millions of everyday products, from household gadgets to industrial tools. Despite the emergence of more complex multilayer boards, single-sided PCBs remain highly relevant due to their straightforward design, ease of manufacturing, and affordability.

What Is a Single-Sided PCB Board?

A Single-Sided PCB Board, also known as a single-layer PCB, is the simplest form of printed circuit board. It consists of a single conductive layer of copper mounted on a non-conductive substrate such as FR-4 or phenolic resin. The copper layer is etched to form the circuit pathways, while electronic components are soldered on only one side of the board.

These boards do not include plated-through holes or inner layers, which limits their circuit complexity but makes them ideal for low-density designs. As a result, they are well-suited for simple electronic applications that don’t require a large number of interconnections.

Advantages of Single-Sided PCB Boards

One of the primary reasons for the continued popularity of single-sided PCBs is their cost-effectiveness. With fewer materials involved, reduced design complexity, and minimal manufacturing steps, production costs are significantly lower than those of double-sided or multilayer PCBs.

Another key advantage is ease of manufacturing. The straightforward layout means that design iterations and prototyping can be completed quickly and at a lower cost. This makes them a popular choice for initial product development phases and applications where rapid turnaround is needed.

Moreover, single-sided PCBs are highly reliable in low-power, low-density designs. Because they have fewer points of failure and no complicated layer transitions, they tend to be more robust in simple applications.

Common Applications of Single-Sided PCB Boards

Despite their simplicity, single-sided PCB boards are widely used across many industries. Their affordability and reliability make them ideal for numerous consumer and industrial products:

Consumer Electronics: Remote controls, calculators, toys, and LED light strips are commonly powered by single-sided PCBs. These devices don’t require high-speed signal transmission, making a single-layer board sufficient.

Power Supplies: Many power supply circuits use single-sided boards to regulate voltage in everyday appliances like chargers and battery packs.

Automotive Electronics: Basic dashboard indicators, interior lighting controls, and entry systems often utilize single-sided PCBs due to their durability and cost advantages.

Industrial Applications: Control panels, timers, and sensor circuits used in industrial settings can be efficiently designed using single-sided PCBs where advanced functionality is not required.

Appliances: Home appliances like microwaves, coffee machines, and washing machines rely on these boards for basic control functions.

Design Considerations for Single-Sided PCBs

While single-sided PCBs are simple in structure, careful design is still essential to ensure optimal performance. Layout considerations such as trace width, spacing, and thermal management play a critical role, especially in power circuits.

Because only one side of the board is used for components and traces, routing space is limited. Designers must plan the layout efficiently to avoid overlaps and ensure the correct flow of signals and power. Additionally, avoiding trace congestion helps improve thermal performance and enhances product longevity.

Material choice also influences board performance. While FR-4 is the most commonly used substrate, alternatives like aluminum can be selected for applications requiring better heat dissipation.

Manufacturing Process of Single-Sided PCB Boards

The manufacturing of a single-sided PCB involves fewer steps compared to more complex board types. The process begins with a copper-clad laminate, which undergoes photoengraving to define the desired circuit pattern. The unwanted copper is etched away, and the board is cleaned and inspected before components are assembled.

Surface finishes such as HASL (Hot Air Solder Leveling), ENIG (Electroless Nickel Immersion Gold), or OSP (Organic Solderability Preservative) are applied to improve solderability and protect the copper surfaces. These finishes enhance durability and ensure a long shelf life, particularly in high-volume manufacturing.

Environmental and Industry Standards

Single-sided PCB boards must still meet industry quality and environmental standards, especially when used in regulated markets like automotive or healthcare. Compliance with RoHS (Restriction of Hazardous Substances) and ISO certifications ensures the boards are manufactured safely and sustainably.

Using lead-free solder, optimizing board design for minimal material waste, and following best practices in PCB recycling all contribute to environmentally responsible production.

Conclusion

The Single-Sided PCB Board remains a cornerstone of the electronics manufacturing industry due to its simplicity, low production cost, and reliability in straightforward applications. Whether it’s powering a household appliance or controlling a basic industrial system, this type of PCB offers a practical solution where complexity is unnecessary.

For businesses and developers looking for efficient and economical PCB solutions, partnering with a reliable manufacturer is key. Viasion Technology provides tailored solutions for single-sided PCB boards with a strong focus on quality, speed, and customer support. If you’re in need of dependable PCB Aassembly China Services, Viasion Technology is a trusted choice for fast, flexible, and cost-effective manufacturing.