Power board assembly is a specialized electronics manufacturing process focused on building printed circuit boards that manage, distribute, and control electrical power within electronic systems. These boards are critical components in applications where stable voltage regulation, high current handling, and thermal efficiency are required. Power board assembly is widely used in industrial equipment, automotive systems, power supplies, renewable energy solutions, and consumer electronics where reliability and safety are non-negotiable.

Unlike signal or control boards, power boards operate under higher electrical and thermal stress. This makes power board assembly a highly technical process that demands careful material selection, precise layout execution, and strict quality control. Every stage of assembly directly impacts performance, efficiency, and long-term durability of the final product.

Role of Power Board Assembly in Modern Electronics

Power board assembly plays a foundational role in ensuring electronic systems function safely and efficiently. These boards are responsible for converting, regulating, and distributing power to sensitive electronic components.

Handling High Current and Voltage

One of the defining characteristics of power board assembly is its ability to handle high current and voltage levels. Thick copper traces, reinforced vias, and robust solder joints are commonly used to support heavy electrical loads. Proper power board assembly ensures minimal power loss, reduced heat generation, and consistent electrical performance even under continuous operation.

Ensuring Electrical Stability

Voltage fluctuations can damage electronic components and reduce system reliability. Power board assembly focuses on stable power delivery by integrating components such as transformers, inductors, capacitors, and power ICs with precise placement and soldering. Accurate assembly helps maintain clean power output and protects downstream circuits from electrical noise or surges.

Key Materials Used in Power Board Assembly

Material selection is a critical factor in successful power board assembly. The materials must withstand thermal cycling, mechanical stress, and electrical load without degrading over time.

High-Performance PCB Substrates

FR4 with higher glass transition temperature, metal-core substrates, and other thermally enhanced materials are often used in power board assembly. These substrates improve heat dissipation and structural stability, especially in high-power applications where operating temperatures are elevated.

Thick Copper and Reinforced Structures

Power board assembly frequently uses thicker copper layers compared to standard PCBs. This allows higher current flow while minimizing resistance and heat buildup. Reinforced pads and vias further enhance mechanical strength and electrical reliability.

Power Board Assembly Process Overview

The power board assembly process involves several carefully controlled stages, each contributing to the overall performance and lifespan of the board.

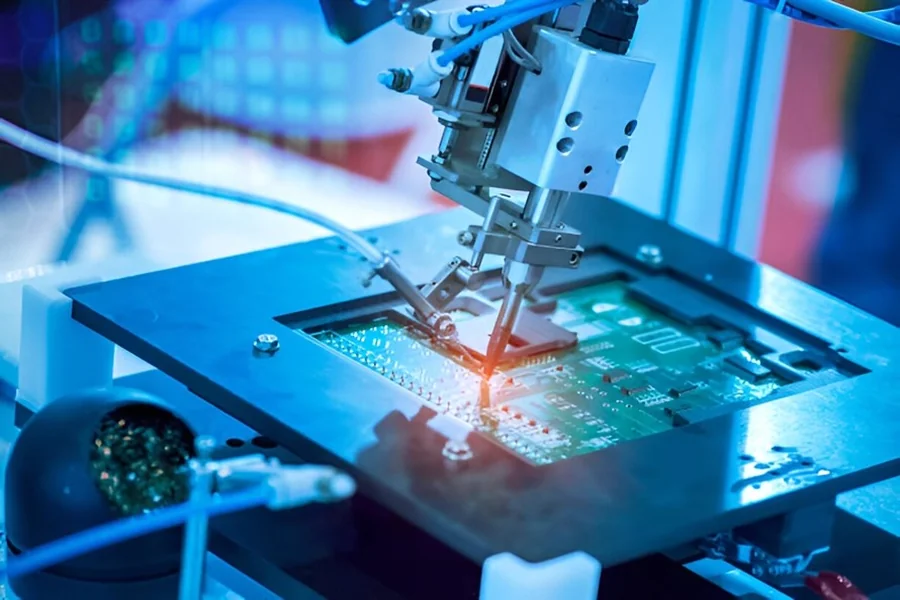

Solder Paste Application and Component Placement

Solder paste is applied with precision to ensure strong electrical connections capable of handling high current. During power board assembly, components such as power transistors, transformers, and connectors are placed with attention to spacing and orientation to support efficient heat flow and electrical safety.

Reflow and Selective Soldering

Reflow soldering is commonly used for surface-mount components, while selective or wave soldering may be applied for through-hole parts that require stronger mechanical support. Power board assembly often combines multiple soldering techniques to ensure all components are securely attached and electrically sound.

Thermal Management in Power Board Assembly

Thermal performance is one of the most critical considerations in power board assembly, as excessive heat can significantly reduce component lifespan.

Heat Dissipation Design

Power board assembly integrates thermal vias, heat sinks, and optimized copper distribution to transfer heat away from critical components. Proper assembly ensures these thermal features function as intended, preventing hotspots and maintaining stable operation.

Reliability Under Continuous Load

Many power boards operate continuously or under heavy load for extended periods. Power board assembly must account for thermal expansion, solder joint fatigue, and long-term material stability to prevent failures in demanding environments.

Quality Control and Testing

Quality assurance is essential in power board assembly because failures can result in system shutdowns or safety hazards.

Electrical and Functional Testing

After assembly, power boards undergo electrical testing to verify voltage regulation, current handling, and protection mechanisms. Power board assembly processes often include load testing to ensure the board performs reliably under real operating conditions.

Visual and Automated Inspection

Inspection methods such as automated optical inspection and X-ray analysis help identify solder defects, misalignment, or hidden joint issues. These inspections are especially important in power board assembly due to the high stresses placed on solder connections.

Applications of Power Board Assembly

Power board assembly supports a wide range of industries where reliable power management is essential.

Industrial and Automotive Systems

Industrial machinery and automotive electronics rely heavily on power board assembly for motor control, battery management, and power conversion. In these environments, durability and consistent performance are critical.

Energy and Consumer Electronics

Renewable energy systems, chargers, adapters, and consumer power devices all depend on efficient power board assembly to deliver safe and stable energy to end users.

Choosing the Right Manufacturing Partner

Successful power board assembly requires experience, advanced equipment, and strict process control. A capable manufacturing partner understands the complexities of high-power electronics and applies industry best practices to ensure quality and consistency.

Conclusion

Power board assembly is a highly specialized process that forms the backbone of reliable power electronics across multiple industries. From managing high current and voltage to ensuring thermal stability and long-term reliability, every detail of the assembly process matters. Working with an experienced provider of China PCB assembly allows businesses to achieve cost-effective production while maintaining high quality standards, making it easier to bring dependable power solutions to market with confidence.